Weatherite’s fully packaged, self-contained pressurisation / RH control solutions are designed and built to meet the demanding requirements of data centre environments, preventing contaminants entering the data halls and avoiding damage to the servers and the valuable data they hold.

Weatherite’s “PressureTec” units condition the outside air so that it can be supplied in to either the cold or hot aisle or directly into the data hall if aisle containment is not deployed.

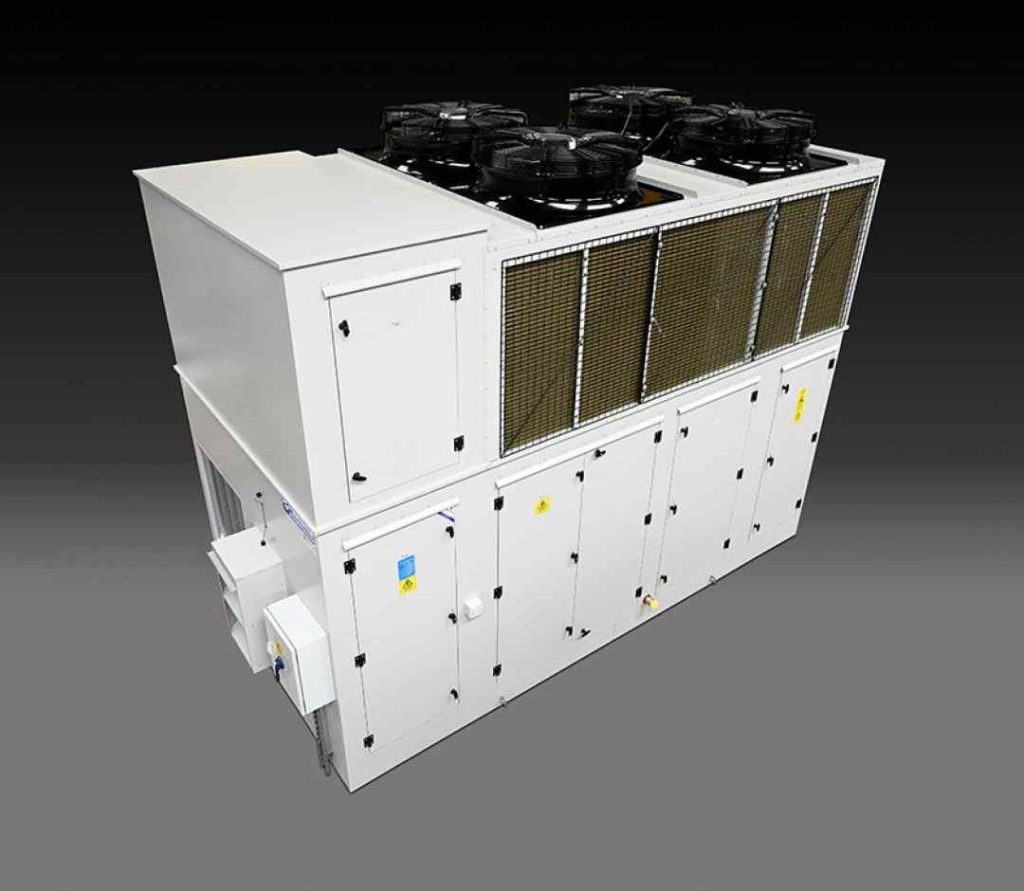

“PressureTec” is a packaged solution, so everything required to provide precise conditioned air is contained within a single unit; no need for remote condensing or humidification units installed elsewhere within the hall. The PressureTec unit just requires an electrical connection, water supply, for the humidifier, drainage and BMS connection for monitoring and alarms. The electrical supply could be via a changeover, providing diverse A & B supplies, backed-up by generators or UPS.

Designed for external environments, our twin wall, fully weather proofed construction ensures the PressureTec units are built for long life with minimal maintenance -protecting the internal components from varying external weather conditions.

What is a Data Centre pressurisation solution

Data centres require positive pressurisation aimed at preventing contaminants entering the data halls and ultimately the servers.

The supplied air is taken from the surrounding outside environment and differs depending on local conditions. Local environments can range from coastal, suffering from airborne sea salt, to industrial or commercial sites with contaminants that could be harmful if they were to reach the data centre servers. The local conditions can also vary from extremely cold and dry winter conditions to very warm and humid summer conditions.

‘Pressurisation solutions’ regulate the amount of ‘conditioned’ outside air supplied into the data hall, in order to ensure the room is kept at positive pressure and supplied within the specified range of temperature and relative humidity.

benefits

- Self-contained- no additional equipment needed.

- Specifically designed to meet the locations environmental requirements.

- Designed to meet your exact requirements.

- Weather protection built in as standard.

- Single point of responsibility for system design, manufacture and commissioning.

- Installation available, if required.

- Latest technologies fitted as standard.

- No need for multi tradespeople.

- Clean filtered air

- Cooling, Heating, humidification and filtration all from one solution

Independently tested to and compliant with the latest ISO/BS/EN standards and ErP Eco-Design Directives and built in accordance with ISO 9001:2015 quality and ISO 14001:2015 environmental standards.

- UK DESIGNED & MANUFACTURED

Pressurisation Solution features

Supply fans

Incorporating the latest free – running impeller technology, high efficiency EC motors together with backward curved blades. Air supply fans provide the latest in powerful, high energy efficiency performance.

Condenser fans

with high efficiency EC fan technology our condenser fans provide compact, durable, high performance, low energy use solutions.

Compressors

Digital scroll compressors, able to provide low turndown of capacity, to match the cooling and de-hum demands precisely.

Casework

‘Double-skin’ insulated casework construction – tested to comply with BS EN 1886 performance requirements – delivering exceptional weather proofing and substantially reduced noise levels.

Integrated Control System

On board control system with pre wired circuit breakers, Trend IQ controller and I/O expansion modules, for unit control and integration with site BMS.

Pre cool condenser

Heat rejection from pre-cool DX coil provides free re-heat during de-humidification mode.

Isolating dampers

Motorised isolation dampers ensure isolation of unit during service and standby modes.

Humidifiers

Using latest technology to provide high efficiency, humidity control and prevent electrostatic discharge (ESD).

Optional smoke and water detectors

Available fitted and wired to the unit controls.

Pressurisation control

Via differential pressure sensors and variable speed fans.

Electronic expansion valves (EEV)

Superheat controllers & condenser head pressure control.

Additional options

- Data Centre Hall pressurisation monitoring.

- Boost modes - to meet each individual client’s particular requirements, for rapid pulldown of conditions.

- Single or multiple electrical configurations - to suite site requirements.

- Hardwired common alarms.

- Alternative controller manufacturer options, if required.

- Smoke detection.

- Fire suppression.

- Fire Dampers.

- Single piece, sectioned or flat-packed, to ensure ease of installation for difficult locations.